4-5

side

grinding

18

Sec. cycle time for

passenger car engine blocks

36

Sec. cycle time for

commercial vehicles

10-700

kg possible weight

of the casting

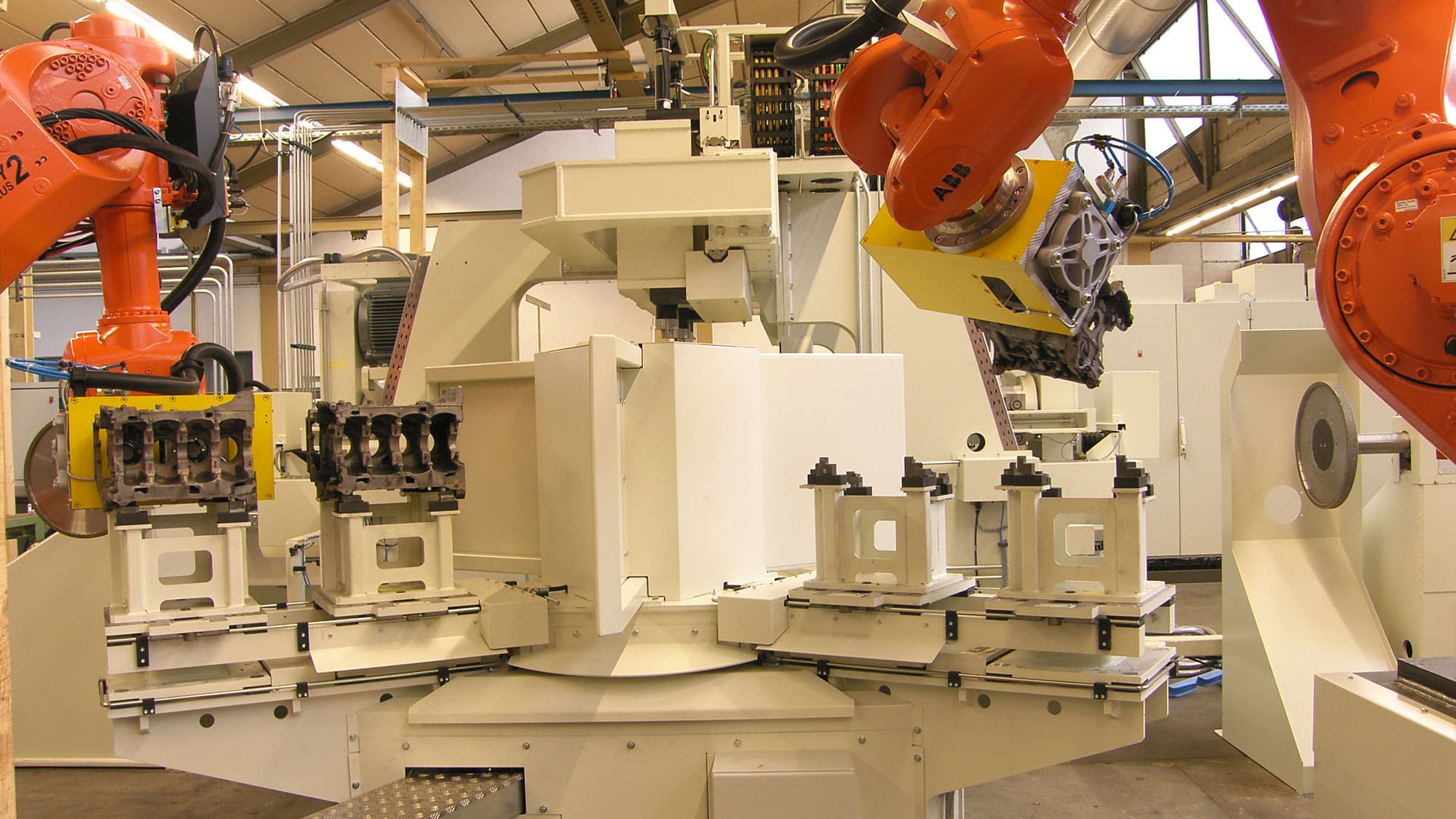

The Reichmann DPM and PM deburring systems for double-sided or single-sided surface grinding deburr castings for both passenger car and commercial vehicle construction. The particularly robust systems have been specially developed for the continuous, unmixed throughput of mass castings in the foundry. The portfolio takes into account castings with all designs from in-line engines to V-blocks from 10 - 700 kg.

3-station loading table enables time-efficient loading and unloading of castings in parallel with machining

efficient 4-side grinding in "black condition”

automatic fixture change by robot

contour grinding with robot

automatic workpiece loading and unloading with robot

3-station loading table enables time-efficient loading and unloading of castings in parallel with machining

efficient 4-side grinding in "black condition”

automatic fixture change by robot

contour grinding with robot

automatic workpiece loading and unloading with robot

Efficient grinding on up to six sides

Reichmann block surface grinding systems are designed for four-sided grinding on in-line blocks or five-sided grinding on V-engines. This makes machining particularly time-efficient.

Flexible robot integration

Integrate robots for engine block handling when loading and unloading the machine or implement complete robotic processing for even greater flexibility.

Automatic type change

If production is changed to a different type of casting, this can be done completely automatically on Reichmann systems. In this case, the machine is emptied within ten minutes, the type-dependent fixtures and machining programs are changed, and then the production of the new castings is started fully automatically. In this way, automated machining of small batches is also worthwhile.

Grinding on „black castings“

To save blasting capacity, more grinding is carried out on the black casting. The blasting of the cylinder crankcases takes place only after deburring, with the decisive advantage that often one blasting process can be saved. Reichmann developed the grinding of "black castings" at an early stage and has successfully installed this process on the market for years.

Reichmann engine block deburring - your benefits

Deburring on the "black cast" to save blasting capacity

Automatic type change within a few minutes

Very short cycle times

Automatic grinding wheel wear compensation for a long tool life

Low maintenance construction

Extremely robust and durable machine construction "Made in Germany"

Your contact person

Rafael Dineiger

Sales Manager International

| Tel.: | +49 7309 875 - 17 |

| Mail: | rdineiger@reichmann.com |