Engineering competence

Innovative solutions

Highest availability

Your partner for

automatic casting finishing

Machines

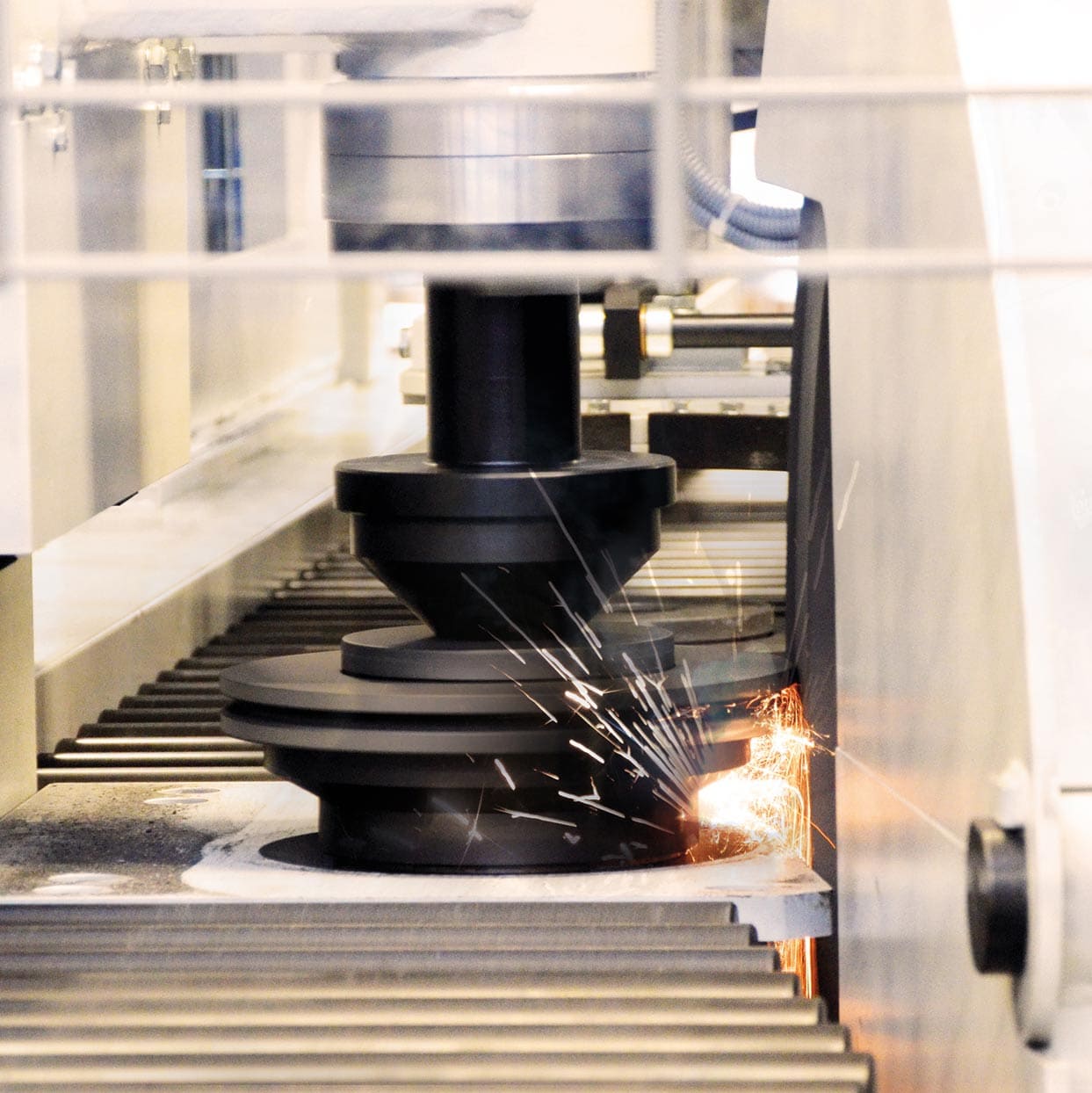

Reichmann Casting Finishing is the world's leading supplier of machines for automatic finishing of castings. In addition to the proven systems for deburring, grinding and cutting castings, Reichmann also offers customized, innovative solutions for special requirements. To further humanize foundry workplaces, the systems can also be equipped with suitable robotic applications.

Automatic grinding machines

Specific deburring, surface grinding or removal grinding of workpieces

Competent partner right from the start.

Thanks to many years of experience in deburring and cutting technology, Reichmann offers a very high level of engineering competence. Together with the customer, we look for the optimal solution for individual process optimization. Aspects such as profitability, amortization, humanization of the workplace, use of space and personal requirements are taken into account to a large extent.

Individual

advice

finding

a solution

Reference visits,

demonstrations

In-House Tests &

Feasibility Studies

Implementation &

Installation

User training &

after sales service

Reliable quality

„Made in Germany“ – since 1918.

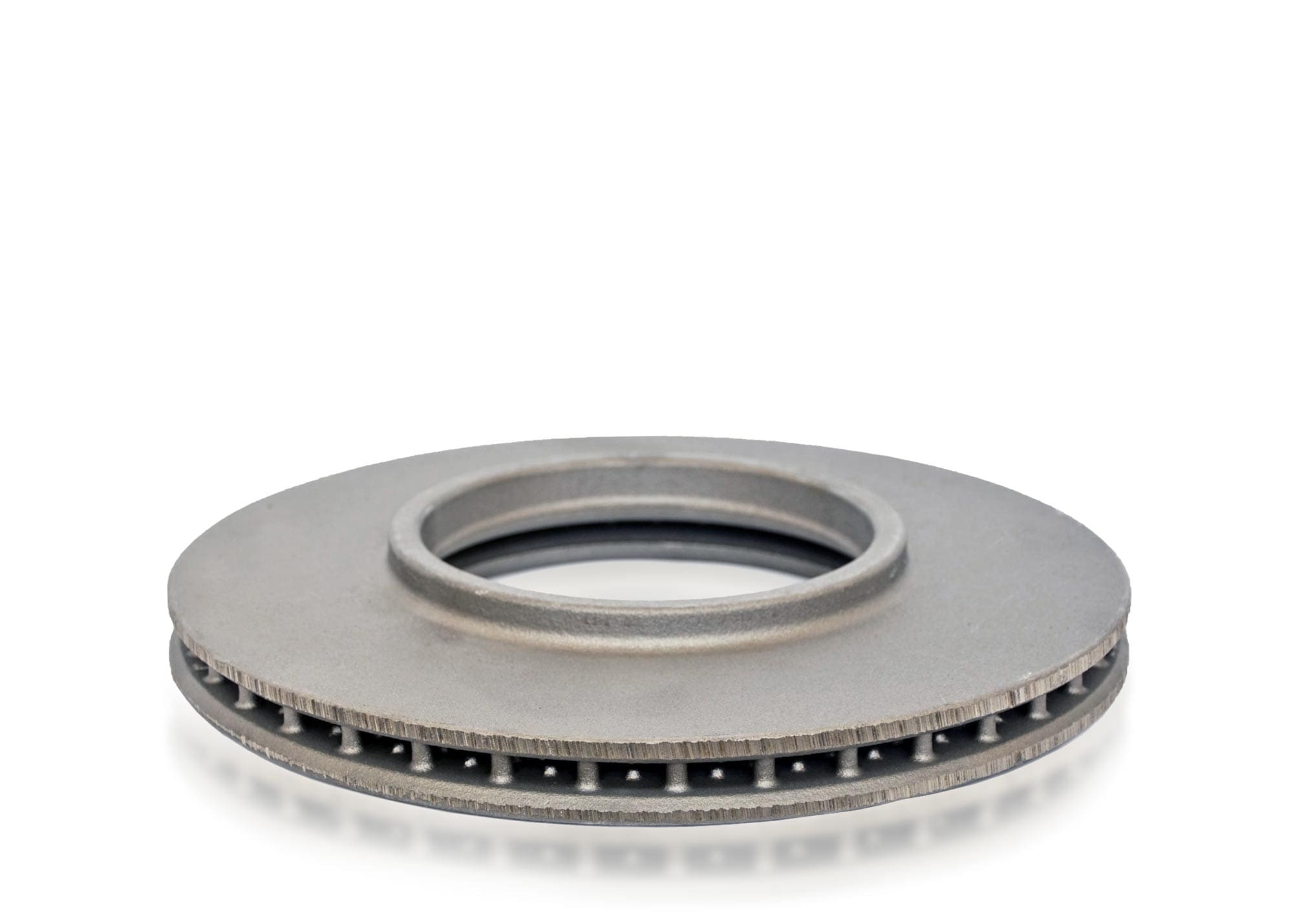

Most brake discs and brake drums worldwide are deburred with Reichmann grinding systems. The consistently high availability over the years, the high-quality results and the durable machine design "Made in Germany" have made us one of the world's leading suppliers of automatic plastering solutions.

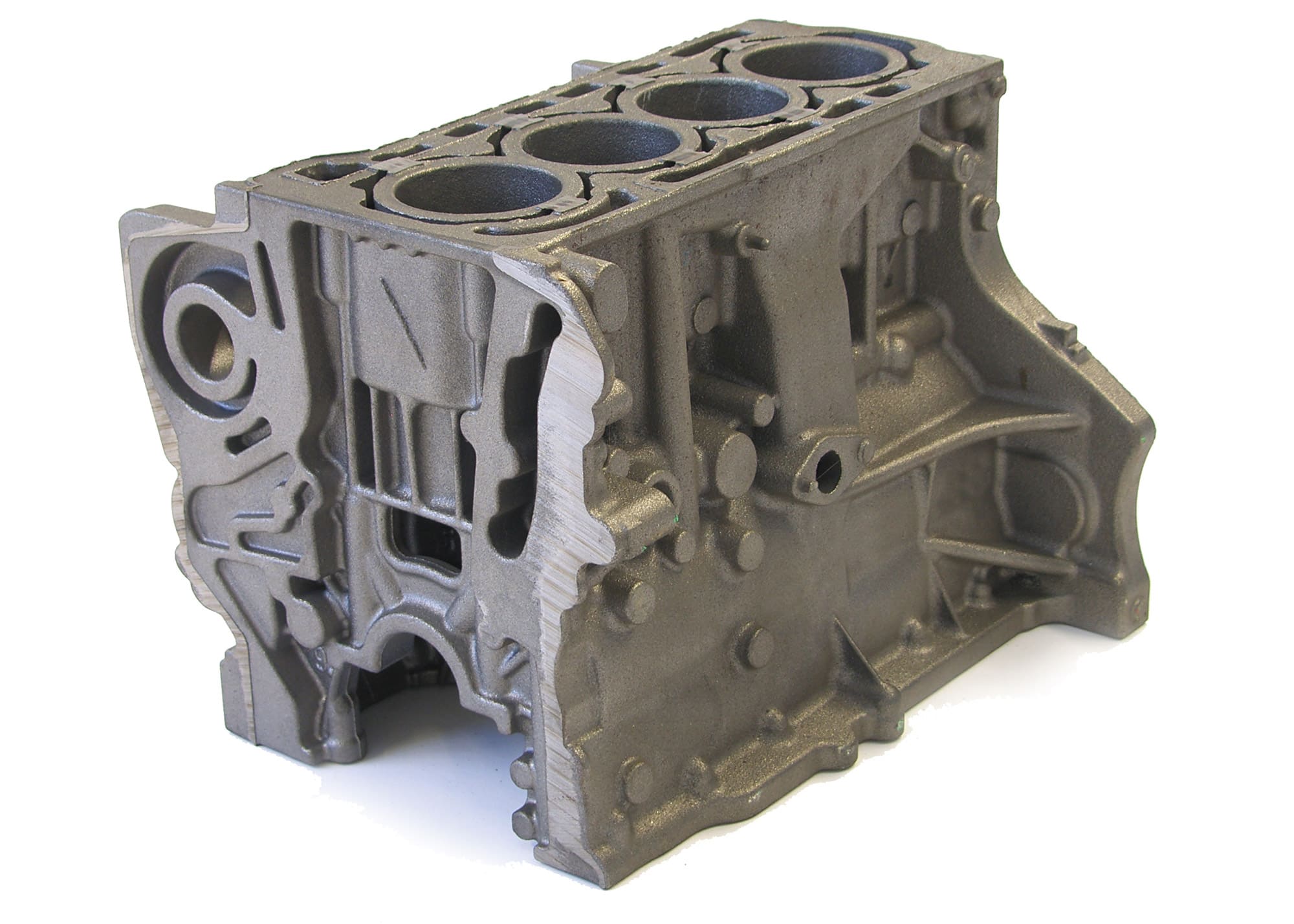

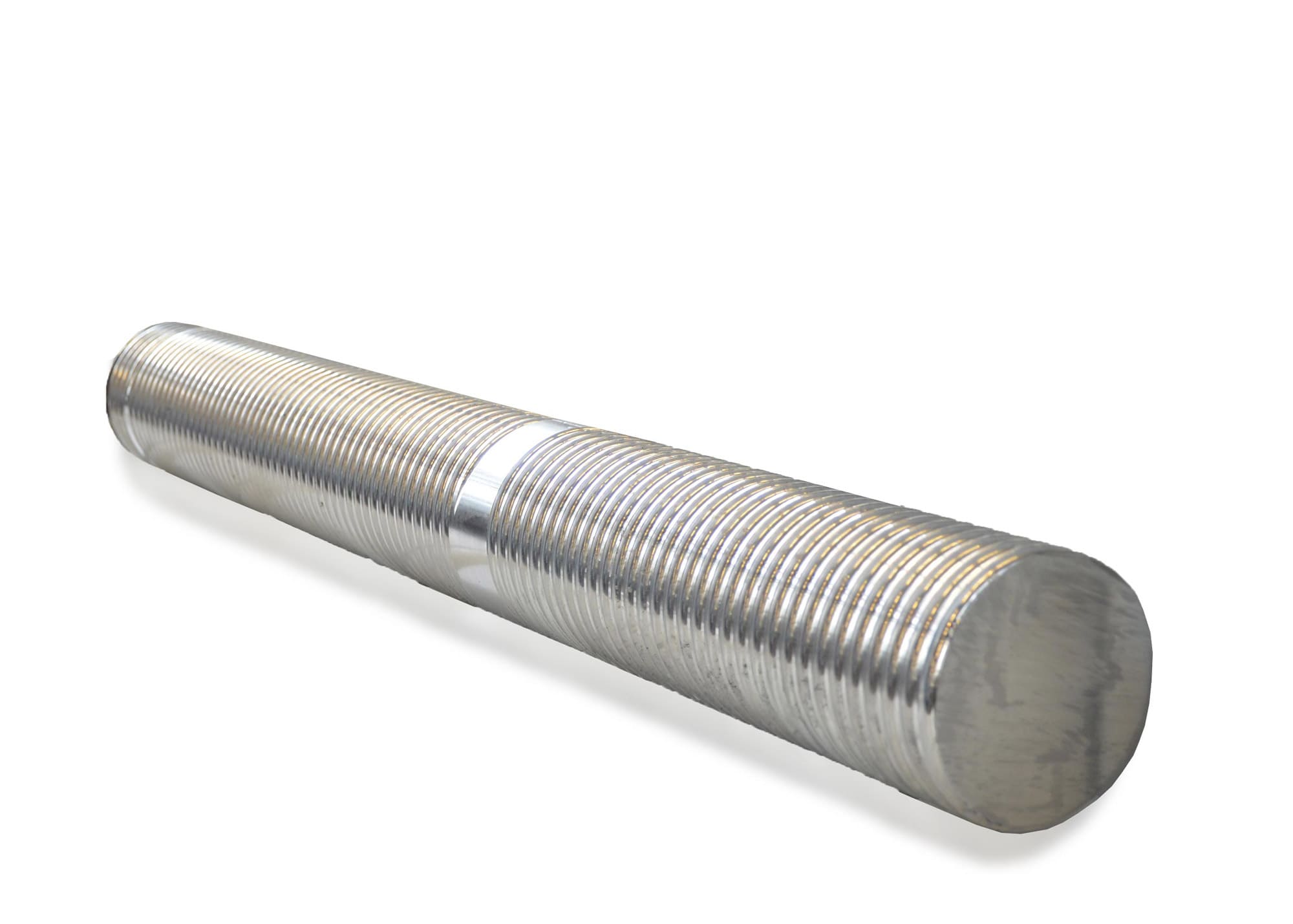

Solutions for your industry

We have the right machine for your cast part or workpiece from a wide variety of industries. If you can't find your industry sector, please feel free to contact us.

Service

At Reichmann you get everything from a single source - turnkey "Made in Germany". We accompany you from consulting and process analysis through development and implementation to after sales. Best production results from day one guarantee rapid amortization.

Find out more about our services.

The company

Reichmann & Sohn GmbH is a family business in mechanical engineering based in Weissenhorn near Ulm in Bavaria. Since its foundation in 1918, the company's core competencies have been grinding and cutting. In the meantime, Reichmann is active with around 80 employees in three independent business units for customers all over the world.