The flexible robot cutting and grinding cell can be equipped for all customer-specific requirements. Robot-based fettling combines the flexibility of the robot with the high performance of Reichmann's grinding and cutting processes and the robust machine design. This enables highly efficient removal of risers and sprue residues from a wide variety of castings, including those in the automotive, aeronautical and medical technology industries. Optionally, the robotic center can be equipped with a conveyor system for the separated risers. In this way, the recirculating material is conveniently conveyed to a container outside the fettling cell without any effort on the part of the operator.

Depending on requirements, workpiece-guided or tool-guided robots can be used.

.jpg)

low process heat prevents structural changes on the casting

high flexibility of the workpieces to be machined

extraction panel with spark pre-separator

high spindle power ensures short cycle times

robot for use in the foundry environment

low process heat prevents structural changes on the casting

high flexibility of the workpieces to be machined

extraction panel with spark pre-separator

high spindle power ensures short cycle times

robot for use in the foundry environment

High cutting and grinding quality without blue grinding

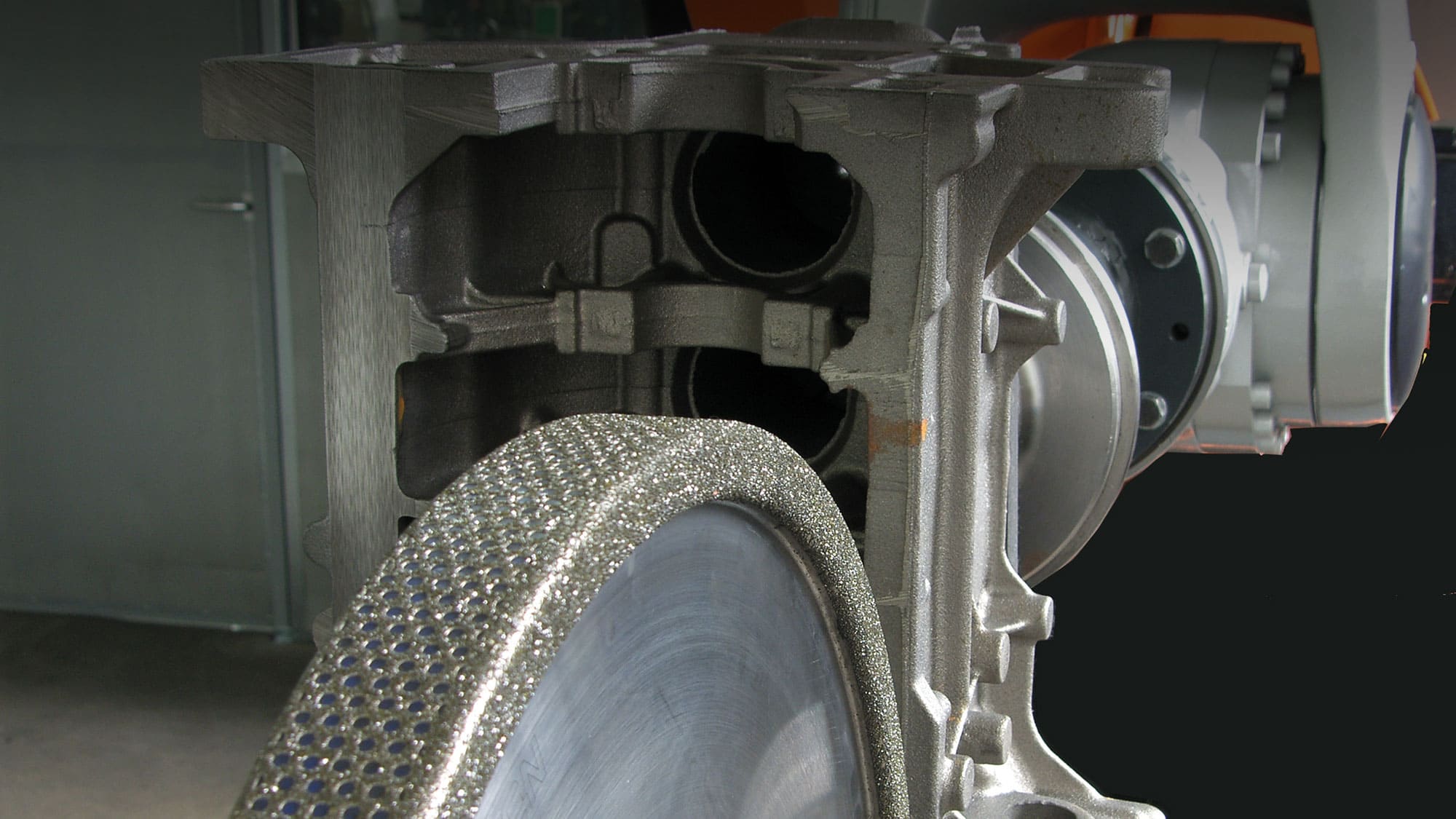

Due to the high performance of the cutting and grinding units in the Reichmann Robot Center, almost no process heat gets into the casting and mold. As a result, risers and sprue residues are precisely removed on all sides in the shortest possible time and the so-called "blue grinding" is avoided. This means consistent grinding quality without cracks and structural changes in the component. The low heat generation also guarantees a long tool life.

Robot-based grinding

The grinding unit is designed with a single or double spindle for grinding cast iron materials with both corundum and diamond wheels. Your advantage: With a double spindle, two different strengths of grinding wheels can be used, making the robot grinding cell even more flexible.

Robot-based cutting

For removing feeders and sprue residues. Our high performance of the cutting unit guarantees efficient and cost-optimized removal of return material. With "CUT TO FINISH" processing, you receive finished cast parts directly from the system, since a subsequent grinding process is not necessary in many cases.

High-pressure belt grinding unit

For removing feeder residues with a removal rate >1 mm per stroke, even with high-alloy steel materials. Almost no process heat gets into the component and tool. For you, this means no structural changes on the casting surface and no crack formation on the workpiece.

ROBOT CLEANING - YOUR BENEFITS

Short cycle times

Long tool life

Consistent cutting and grinding quality

Humanization of foundry jobs

High flexibility

High quality of the results without blue sanding, cracking or structural changes

Downloads

Your contact person

Rafael Dineiger

Sales Manager International

| Tel.: | +49 7309 875 - 17 |

| Mail: | rdineiger@reichmann.com |