350 - 800

mm selectable

separating disc diameter

5

to maximum workpiece weight

(in standard equipment)

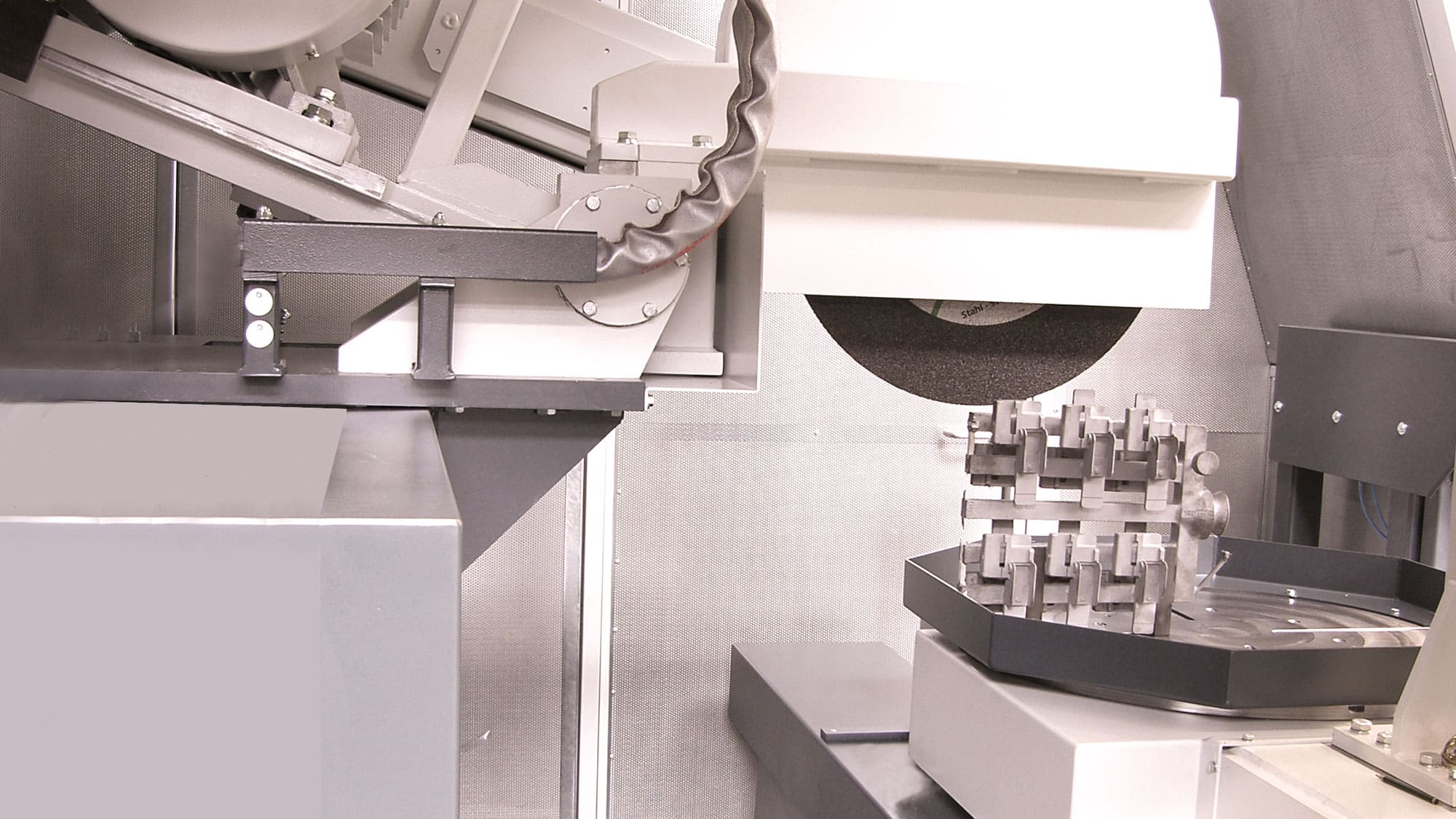

From the manual to the fully automatic cut-off machine

The portfolio of Reichmann cut-off machines ranges from the manually operated hand cut-off machine to the fully automatic cut-off center. The cut-off grinding machines remove sprues and circuit material from castings made of investment castings, gunmetal, cast steel, gray cast iron, as well as titanium and superalloys of various sizes and shapes.

laser-projected cut-off line ensures precise cut-offs

low maintenance spindle due to lifetime lubrication

sound-proof cabin for high safety and reduced noise levels

spark pre-separator for process-safe extraction

cut-off grinding in “black condition”

low heat generation in the casting prevents blue grinding

laser-projected cut-off line ensures precise cut-offs

low maintenance spindle due to lifetime lubrication

sound-proof cabin for high safety and reduced noise levels

spark pre-separator for process-safe extraction

cut-off grinding in “black condition”

low heat generation in the casting prevents blue grinding

„Cut-to-finish“

Reichmann cut-off lines guarantee consistent cut-off quality with enormous repeatability. By means of the "cut-to-finish" performance, it is often possible to cut so close to the workpiece that further post-treatment is no longer necessary. This increases economic efficiency and saves time.

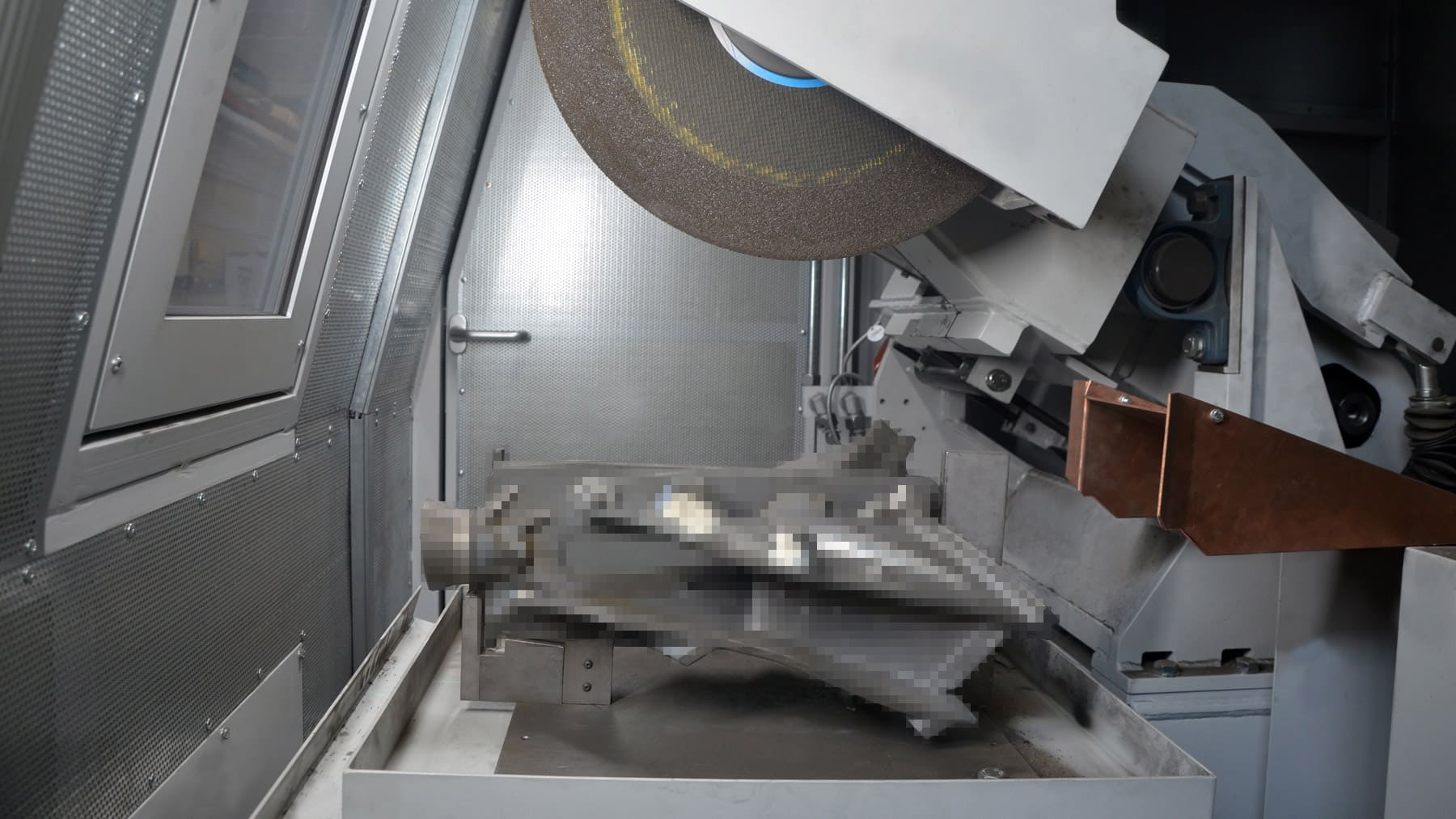

High cutting performance

Due to a high drive power and short contact times of the cut-off wheel with the casting, the process heat occurring during the cutting process is largely dissipated with the sparks and the cut-off abrasion. The result is a cut-off without blue grinding and structural changes, which is particularly important for safety parts in the automotive or aerospace industries.

Your benefits:

Short cycle times

High efficiency thanks to cut-to-finish performance

Possibility of machining sandy surfaces

Contribution to the humanization of foundry workplaces

High cut quality without blue grinding or microstructural changes

Highest availability and long service life

Your contact person

Rafael Dineiger

Sales Manager International

| Tel.: | +49 7309 875 - 17 |

| Mail: | rdineiger@reichmann.com |

After 13 years, we have decided to buy a second Reichmann cut-off machine. The new Reichmann TS 600 complements our existing TS 800 in cut-off grinding of smaller castings. Due to the similar design and the robust, durable construction of both machines, we benefit from a very high availability, efficiency and low spare parts inventory. Added to this is the high power density, which allows us to separate our steel castings from risers without heat input and thus without structural changes. Very cost-efficient and sustainable for us is the possibility to reuse used grinding wheels from the TS 800 on the smaller TS 600 cut-off machine.

KSB SE & Co. KGaA

Pegnitz, Germany