4

machine sizes

1.000

kg max. casting weight

2200

mm max. casting

dimension

2-3

tools or optional

tool changer

Extraordinary simple

The new MAUS series offers the currently easiest available teach-in method for programming new castings. The basis is the modern Windows 10 based interface, which can be intuitively operated by anyone without prior knowledge. With unique function favourites, standardized fixture interfaces and a large selection of standard tools, your castings will be ready for automatic fettling in no time.

Always one step ahead

The IIoT-capable user interface of the automatic casting finishing system allows targeted collection, evaluation and integration of data (e.g. motor currents). This allows downtimes to be identified before they occur and planned in a targeted manner. Increase your productivity and reduce costs.

New fixture in no time

Build yourself a suitable fixture for your casting in no time. To create a fixture, you can either use 3D data or a workshop solution based on our standardized fixture interface. Optionally, you can get active fixtures and customized solutions. We also support you in future grinding tasks with fixture creation and sequence programming.

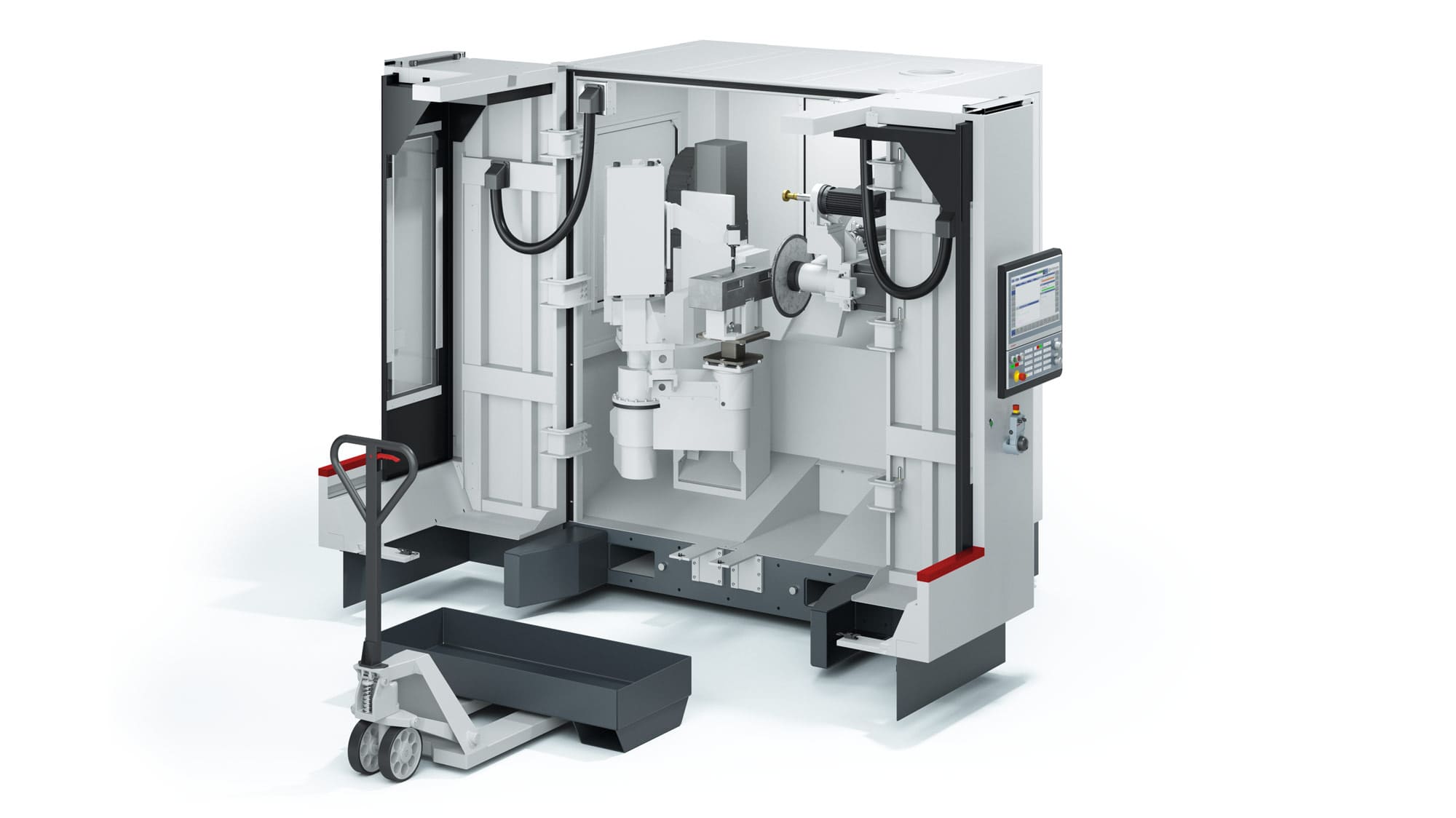

Universal chuck

The MAUS automatic grinding machines can be equipped with a universal chuck specially developed by Reichmann. The chuck is free of media in the machining area and has swivel arms with a very high effective circle without retooling. The effectively encapsulated swivel arms prevent the ingress of dust and thus ensure a long service life and high reliability.

High degree of completion

In the MAUS grinding machines you get up to three servo-driven tools without changeover time as well as optional clamping stroke and clamping pressure monitoring, program adjustment by online laser measurement and a fully integrated chip conveyor. This enables you to achieve an even higher finishing grade with the highest quality and precision.

Economical with the smallest batch sizes

Thanks to the short setup times or machining in mixed operation, you can achieve economical automated machining even with very small batch sizes. With two or three tools suitable for your process and an optimally dimensioned spindle power, you benefit from high cost-effectiveness, energy efficiency and reduced cycle times.

Reliable and competent partner

Save costs through the highest availability, quality and the robust machine design of Reichmann systems "Made in Germany". We accompany you from consulting and process analysis through development and implementation to after sales. Best production results from day one guarantee a fast return on investment. Rely on our many years of experience and competence in automatic grinding.

Ergonomics on all levels

Highest comfort for the user comes as standard with us.

The MAUS casting finishing centres score with particularly good accessibility for operation, loading, programming, cleaning and maintenance. Optimized walkways, an ergonomic insertion height of the castings and safety devices for the operator ensure that your employees enjoy working on the machine.

The machines allow easy access for cleaning and maintenance.

The effective encapsulation of the axes and the central lubrication system reduce maintenance work and downtimes to an absolute minimum.

The extra-large chip drawer or the optional top-floor chip conveyor minimize cleaning intervals. The chip drawer can be conveniently emptied with a forklift or lift truck.

Dust extraction takes place at the ideal point in the machining area.

Clear, dirt-resistant operating point with all data at hand: network drives, remote access, documentation in the machine.

The machines allow easy access for cleaning and maintenance.

The effective encapsulation of the axes and the central lubrication system reduce maintenance work and downtimes to an absolute minimum.

The extra-large chip drawer or the optional top-floor chip conveyor minimize cleaning intervals. The chip drawer can be conveniently emptied with a forklift or lift truck.

Dust extraction takes place at the ideal point in the machining area.

Clear, dirt-resistant operating point with all data at hand: network drives, remote access, documentation in the machine.

Your benefits with the MAUS machines:

Significant time savings and higher throughput compared to manual fettling

Shorter set-up times and lower qualification requirements for personnel

High acceptance by personnel due to ergonomic design, safety features & intuitive operation

Compact design for easy transport and quick installation

Everything from a single source - from consulting & process analysis to development & implementation to after sales

Best production results from day one guarantee a fast return on investment

Your contact person

Rafael Dineiger

Sales Manager International

| Tel.: | +49 7309 875 - 17 |

| Mail: | rdineiger@reichmann.com |

With the new automatic grinding center from Reichmann, we were able to more than halve our cleaning time. The fast training and set-up of the machine for new parts facilitates and accelerates the work enormously. In the meantime, we can even train new employees ourselves to operate the system. For service questions, we appreciate the fast response time and the direct line to a competent service contact.

Trompetter Guss GmbH & Co. KG