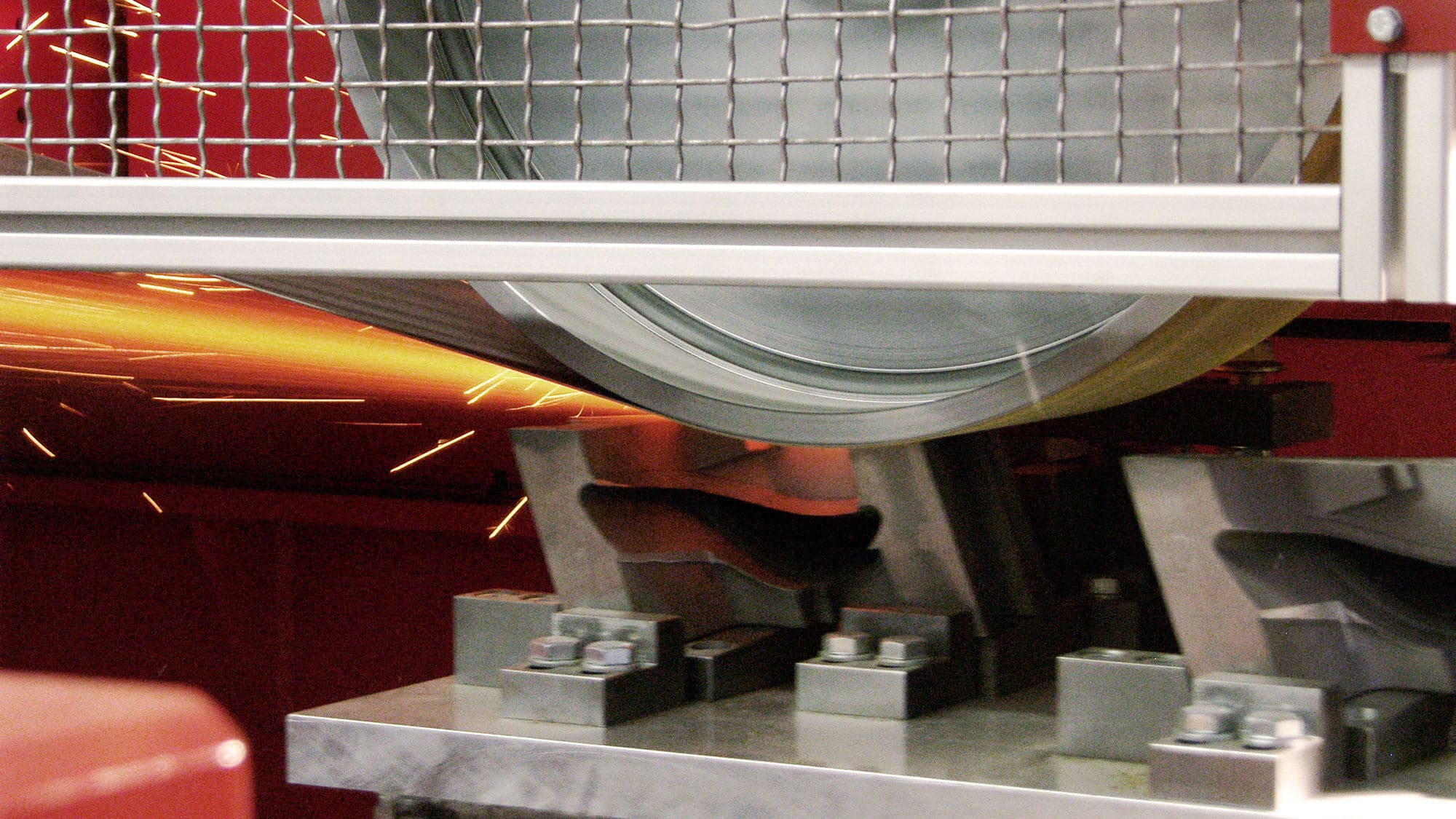

Reichmann HBM high-pressure belt grinding systems impress with high stock removal rates, negligible temperature input and long tool life when machining high-alloy and difficult-to-machine materials. Harmful structural changes caused by process heat are thus reliably avoided.

The machines combine stable mechanical engineering, high drive power at high contact pressure and the use of specially manufactured abrasive belts. This combination enables the belts to achieve significantly higher stock removal rates without vitrification, thus maximizing the economic utilization of the equipment.

The high-pressure belt grinding systems are designed for continuous operation in the foundry environment. Adapted and scalable machine designs are available for different workpiece sizes and applications.

Typical applications for high pressure belt grinding

- Removal of sprue supernatants on investment castings

- Components for wear castings: e.g. plates for cement mills, teeth for excavator blades, gas turbine blades

- Components for medical technology: e.g. joints, implants, etc.

- Components for the aircraft industry: e.g. turbine blades

- Components for automotive engineering: e.g. impellers for turbochargers, "container corners", etc.

the process heat is safely dissipated

line laser for fast adjustment of the height

NC-controlled grinding belt adjustment

cost effective clamping system

the process heat is safely dissipated

line laser for fast adjustment of the height

NC-controlled grinding belt adjustment

cost effective clamping system

Your benefit:

NC-controlled machining enables shortest cycle times

Good accessibility for maintenance and cleaning activities

Low maintenance spindle due to lifetime lubrication

Extremely economical use due to long service life and less frequent replacement intervals of the sanding belt

Low dust emissions by means of extraction with spark pre-separator

Sealed drive compartment, i.e. the drive motor and control components are not located in the work area

Your contact person

Rafael Dineiger

Sales Manager International

| Tel.: | +49 7309 875 - 17 |

| Mail: | rdineiger@reichmann.com |