The Reichmann cast cleaning centers offer flexible automated processing of a wide variety of workpieces. Depending on your workpiece or process, the fettling machines or the robot center can be equipped with the required tools and spindle power. We will be happy to advise you in order to find the right solution for you.

Deburring Grinding Machines S1

The Reichmann S1 deburring grinding machines are ideally suited for high production numbers in a single-variety, continuous run. The round part grinding machine removes burrs and sprue residues on the inner and outer diameter and convinces with extremely short cycle times of up to 5 seconds per casting.

Round part grinding machines RFG

Round part grinding machine for specific round part machining on the outside, inside and on the head surface. The rigid chuck has a large useful range and a centering effect. Thus, the round part is brought into shape during grinding.

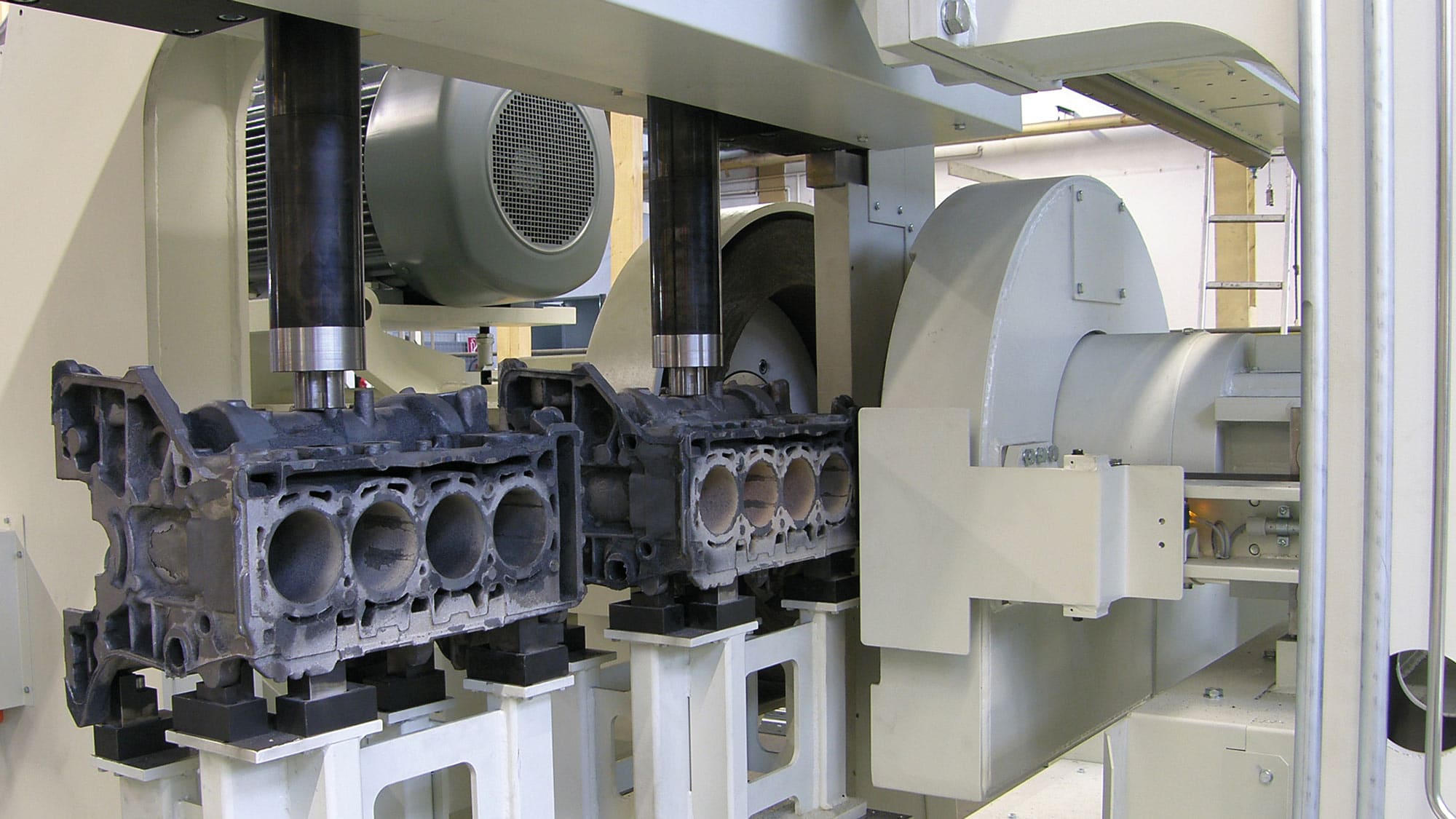

Surface grinding machines DPM & PM

The DPM and PM surface grinding machines are particularly robust systems for the continuous, unmixed throughput of mass castings in the foundry. The grinding machines convince with very short cycle times of up to 18 sec. for 4-side grinding on engine blocks, cylinder heads or crankcases.

High-pressure belt grinders HBM

Reichmann uses the high-pressure belt grinding process for the removal of sprue residues on investment castings. High-pressure belt grinding guarantees the highest stock removal rates and the longest tool life.

Cylindrical grinding machines AS

The AS automatic cylindrical grinding machine grinds round bars on the outer diameter and on the end face.