10

kg cutting

capacity per hour

70 - 10

mm round

parts diameter

100%

customer-specific

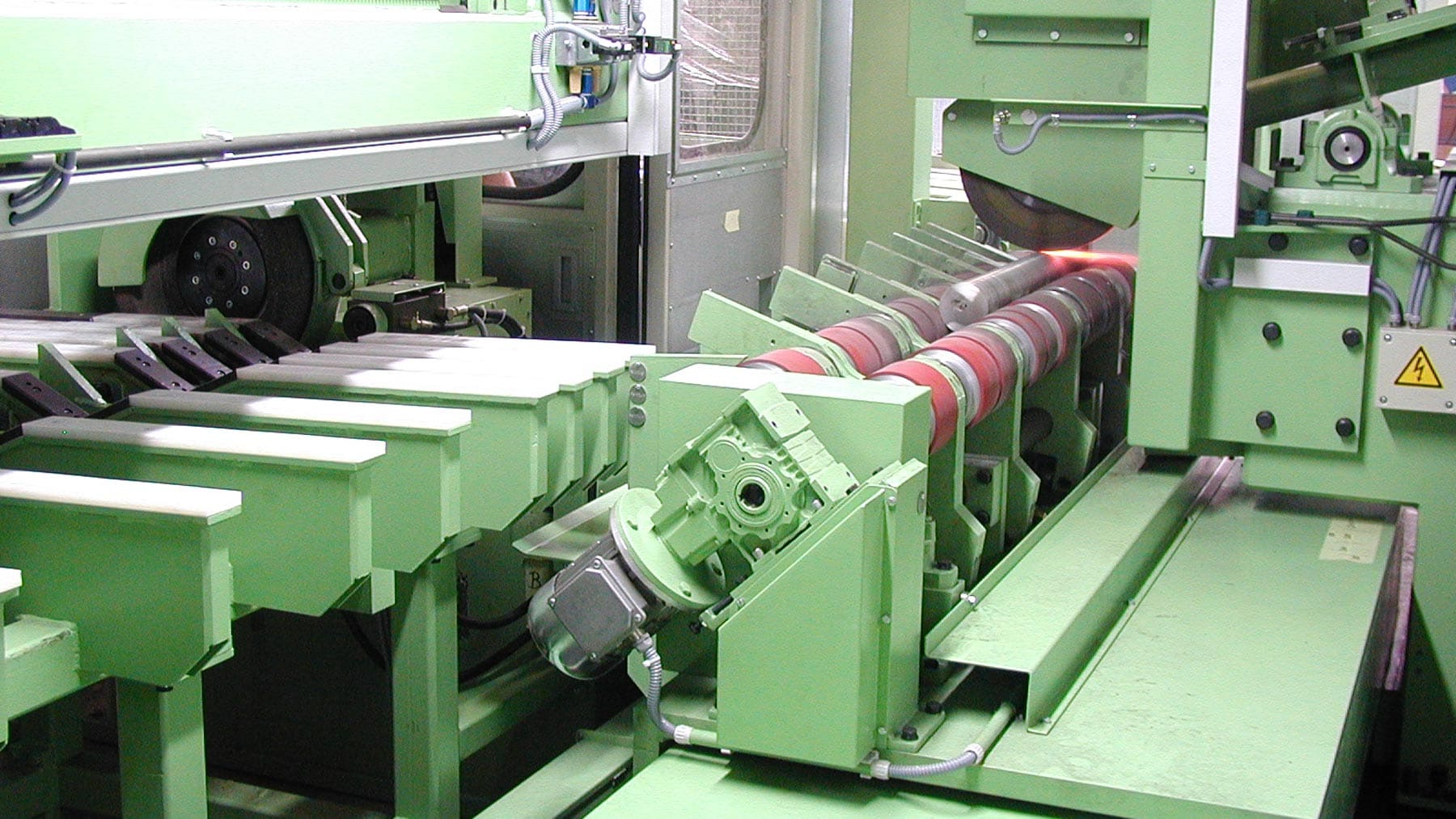

The AS automatic cylindrical grinding machine was developed for the surface grinding of super alloy bar stock used in the manufacture of high-tech investment castings such as turbine blades, surgical implants or turbochargers.

The grinding machine automatically loads, grinds and unloads diameters from 70 mm to 210 mm and from 250 mm to 1550 mm in length. After the external cylindrical grinding, the machine automatically grinds the face of the components flat.

WORKPIECES

- Round bars cast in gravity die casting, not blasted

- Nickel super alloy bars

Your benefits:

Automatic cut-off wheel wear compensation in the machining cycle

Low-maintenance machine design for continuous use in the foundry environment

Process-reliable extraction to protect the operating personnel

Bars can be ground in different diameters and lengths

Your contact person

Rafael Dineiger

Sales Manager International

| Tel.: | +49 7309 875 - 17 |

| Mail: | rdineiger@reichmann.com |