Automatic grinding of engine components

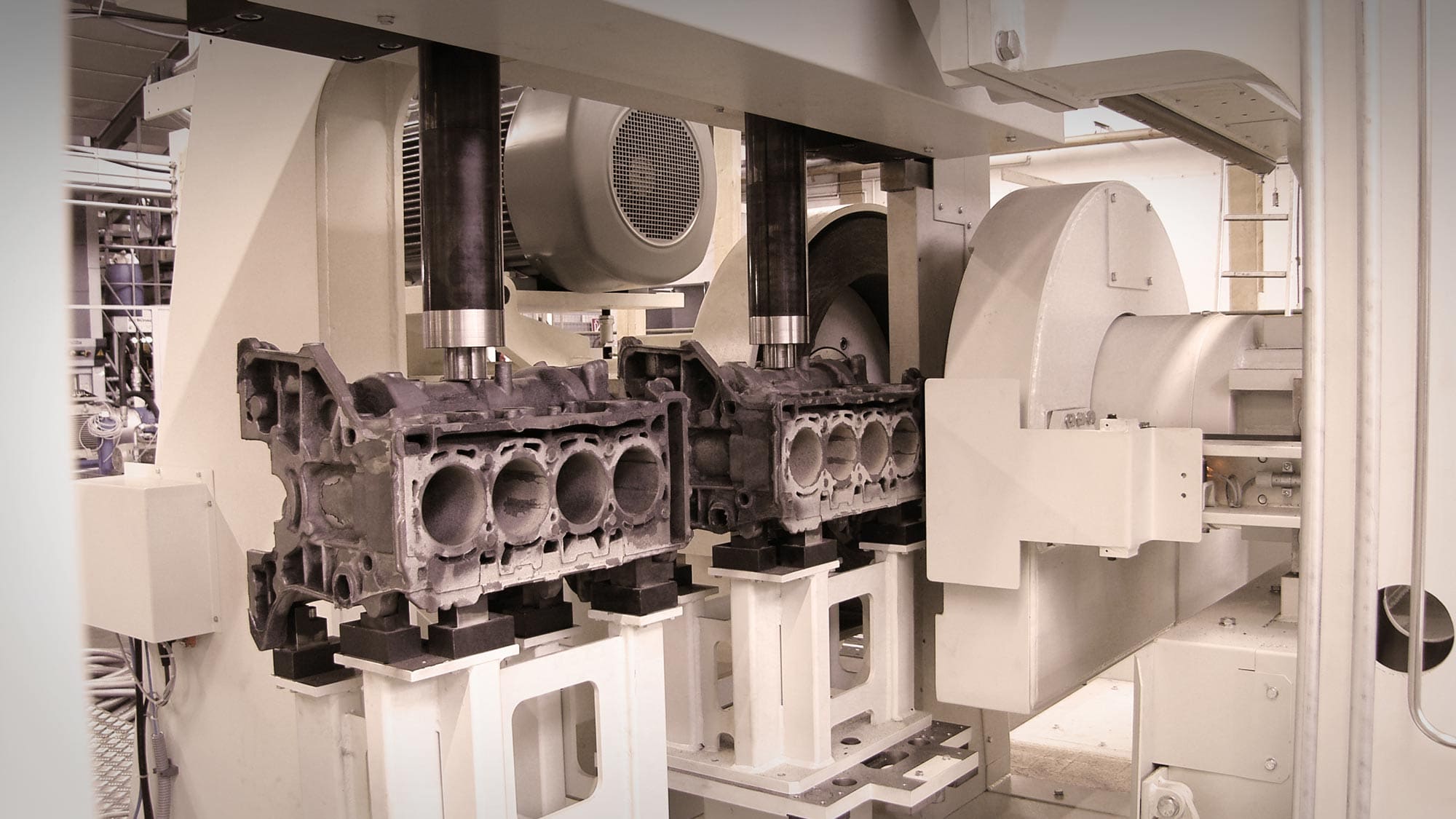

Reichmann grinding plants and cutting-off plants are used for the economical and efficient machining of mass castings in the automotive industry such as engine blocks, cylinder heads or crankcases for passenger cars and commercial vehicles.

Reichmann grinding systems can also be used to machine engine blocks or cylinder crankcases in black castings prior to sandblasting. Blasting of the castings then takes place only after deburring with the decisive advantage that a blasting process can often be saved.

Surface grinding machine DPM & PM

The DPM and PM surface grinding machines are particularly robust systems for the continuous, unmixed throughput of mass castings in the foundry. The grinding machines convince with very short cycle times of up to 18 sec. for 4-side grinding on engine blocks, cylinder heads or crankcases.

Automatic grinding center Maus 600-2200

The Maus casting finishing center is designed for flexible cutting and grinding of castings with up to three tools. The fettling center offers high flexibility for small to medium production numbers and fast teach-in for new castings. Machining takes place efficiently in parallel with loading and unloading.

Robot Center

For the machining of mass castings such as engine blocks or cylinder heads, the Robot Center can be efficiently combined with the DPM or PM surface grinder. By having the robot take over preparatory work, a higher degree of completion is achieved.