140-1600

mm casting diameter

with 2 sizes

50

mm max.

casting height

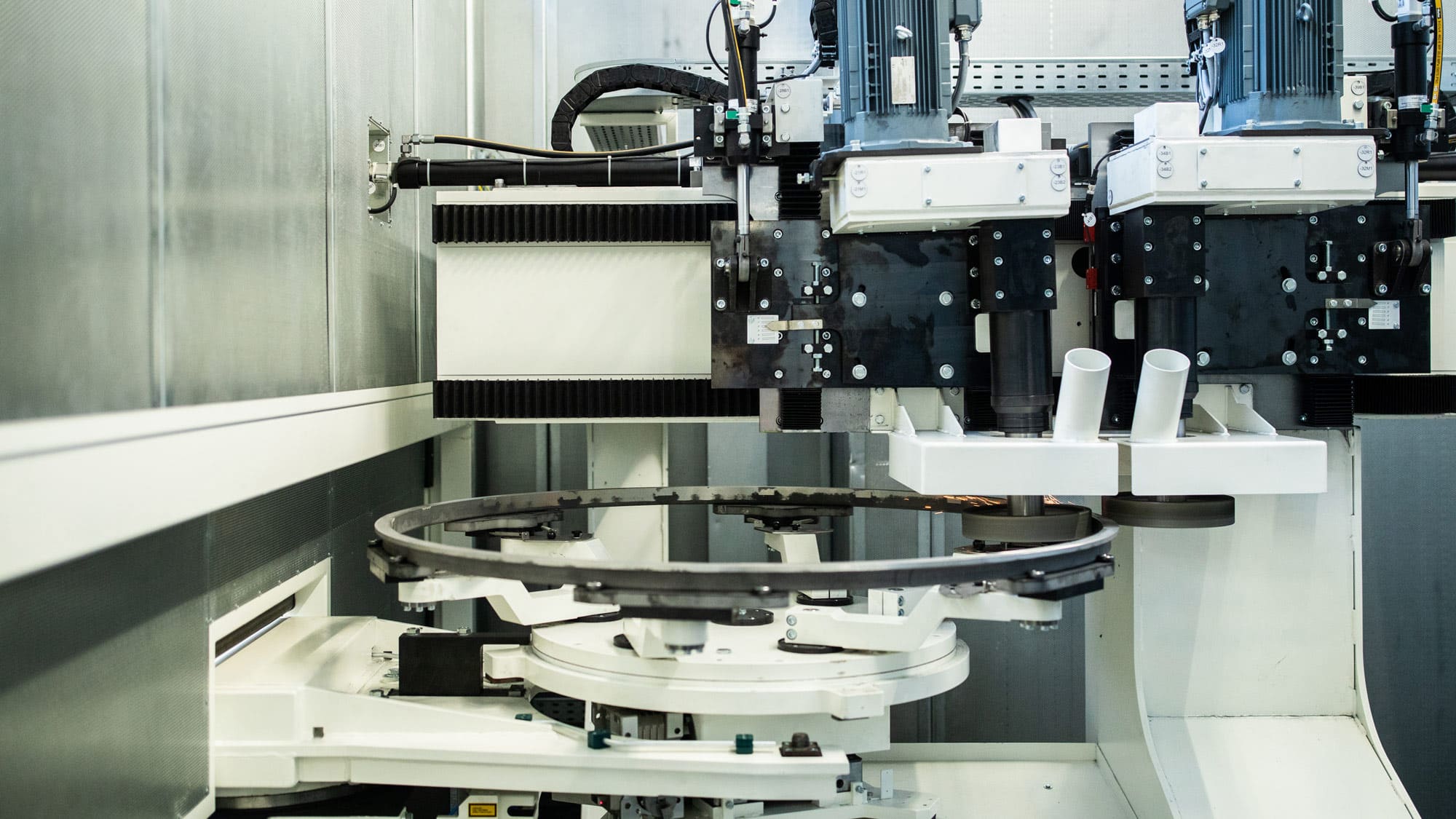

The RFG automatic deburring machine is designed for deburring gasket rings or similar round parts.

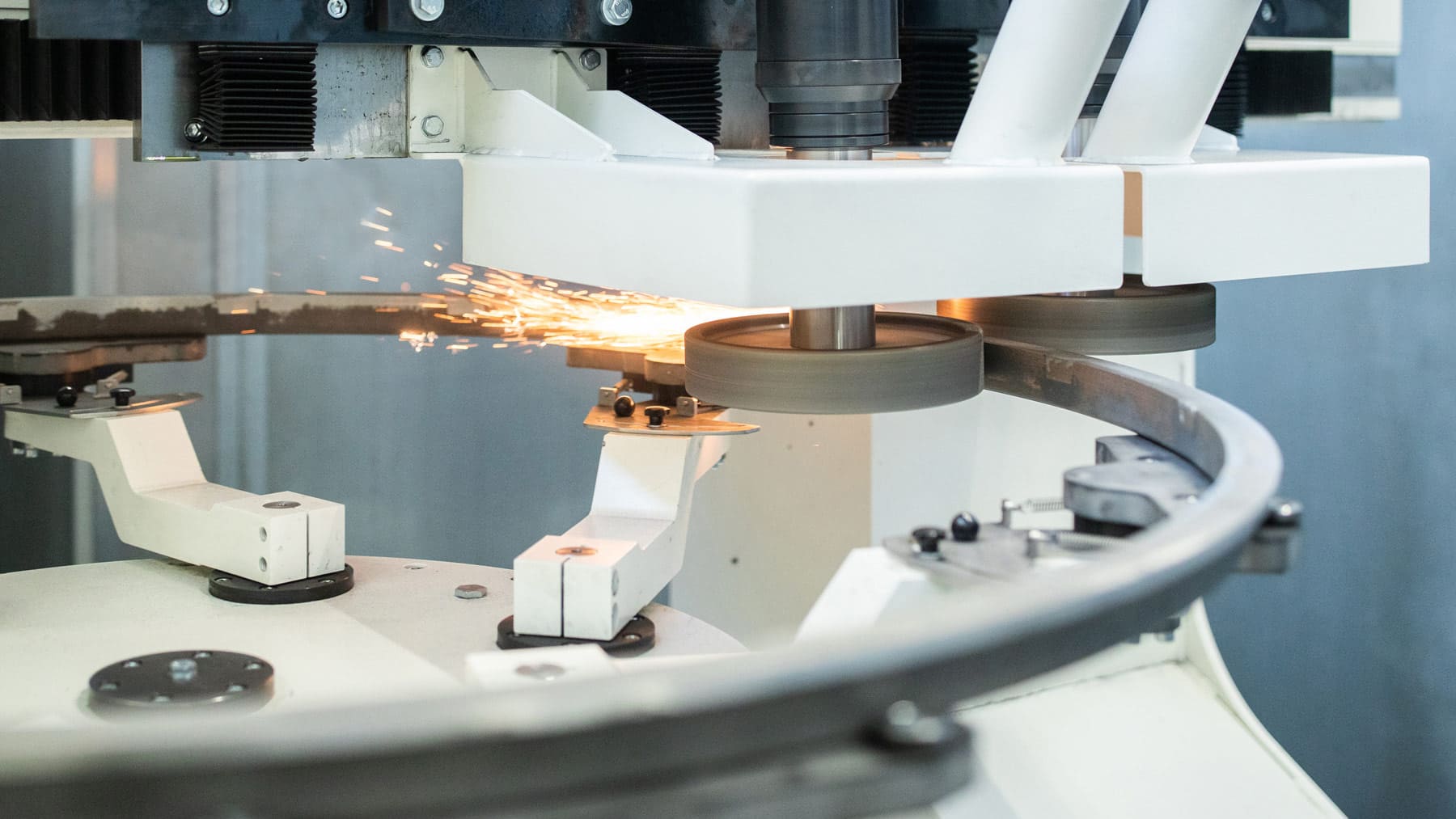

The round part grinding machine processes castings externally, internally and on the head surface. The rigid chuck has a large effective range and a centering effect. In this way, the round part is brought into shape during grinding. The chuck securely holds the round parts and swivels the clamped parts into the machine for machining. The outer and inner diameters of the castings are ground simultaneously. This saves valuable time and ensures a particularly efficient process. During machining, the castings are loaded and unloaded.

grinding on the head surface as well as on the outer and inner diameter

centering effect of the chuck brings the round part into shape during grinding

the low-rigidity chuck has a large useful range

grinding on the head surface as well as on the outer and inner diameter

centering effect of the chuck brings the round part into shape during grinding

the low-rigidity chuck has a large useful range

Universal chuck

RFG's media-free universal chuck enables particularly efficient machining of the highest quality for a large diameter range from 500 to 1600 mm with only 2 sizes. The entire clamping range can be used without retooling, only the contact zones to the workpiece are covered by adapted clamping jaws. The central drive of the clamping arms ensures optimum concentricity even with deformable parts.

Your benefits:

Large clamping range without changeover work with variable clamping force

Self-centering

Durable design due to safely encapsulated, integrated rotary drive

Suitable for alternating feeding

Finishing on the inside and outside diameter or on the head surface

Wear- and maintenance-free design

Your contact person

Rafael Dineiger

Sales Manager International

| Tel.: | +49 7309 875 - 17 |

| Mail: | rdineiger@reichmann.com |