Our NTS wet cutting machines are successfully used for all difficult-to-cut materials in general engineering. The machines offer highly accurate cutting according to angle and length dimension while avoiding burr formation and blue grinding. Typical applications are cutting and trimming tasks for

- Guide rails and bars;

- racks;

- Piston rods - soft, hardened, hard chrome plated;

- ball screws and threaded spindles;

The cut-off process convinces by very short cutting times, which are significantly shorter than the usual sawing times.

Soundproof cabin protects the operator from noise, lubricant mist & flying sparks

Fully automatic grinding process

Automatic blade wear compensation

Optional: Marking unit for cut parts

White cut thanks to low heat input

Soundproof cabin protects the operator from noise, lubricant mist & flying sparks

Fully automatic grinding process

Automatic blade wear compensation

Optional: Marking unit for cut parts

White cut thanks to low heat input

Cut-off surface with "white cut

Due to the extremely short cycle times during the cut-off grinding process, the resulting process heat is dissipated with the chips. As a result, neither the material to be cut nor the tool are heated. The result is a smooth, burr-free and undyed cut-off surface (white cut) without blue grinding or material changes. Due to the high angular and length accuracy, no further finishing is necessary. In addition, you benefit from a long tool life.

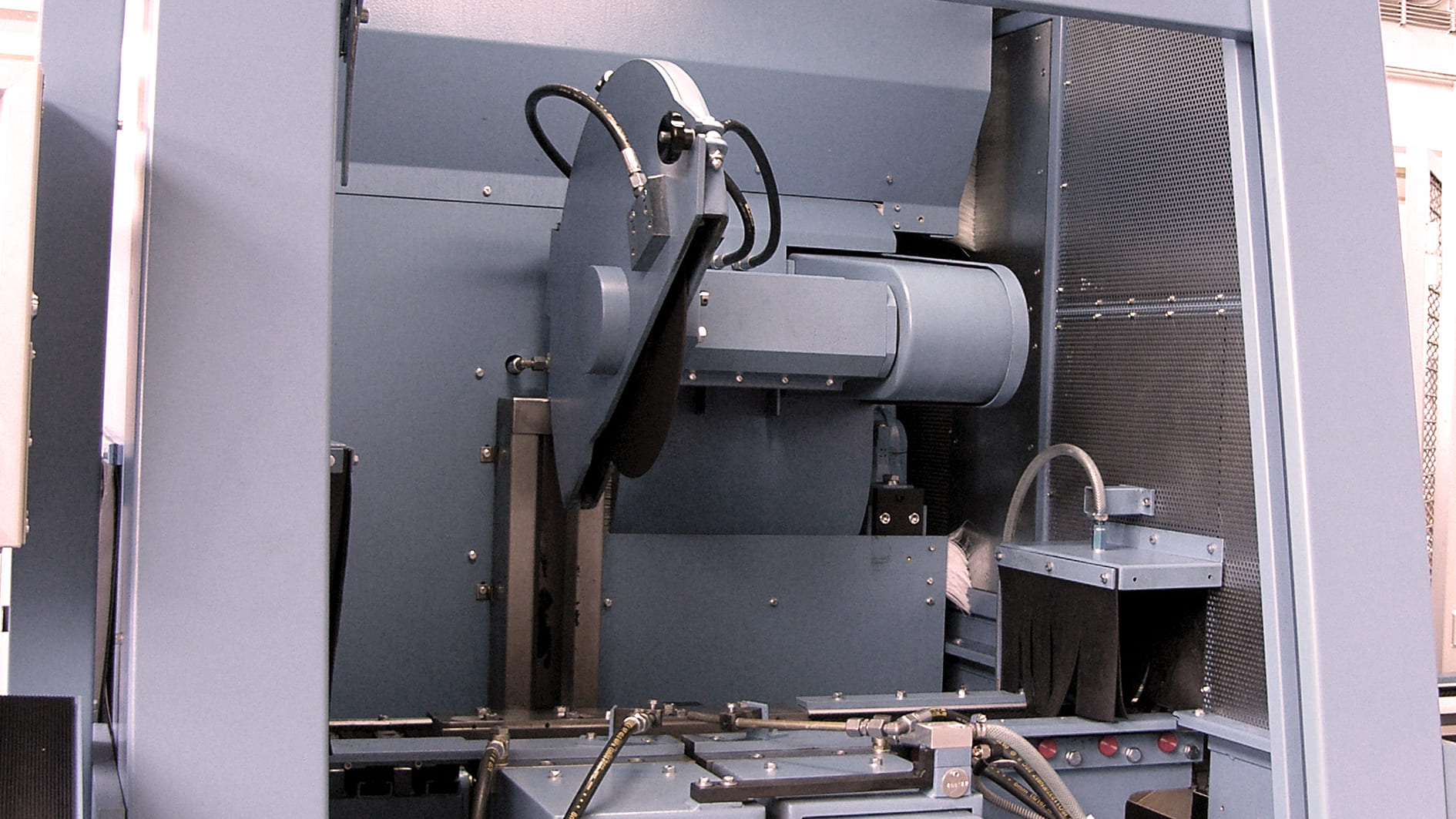

Wet cutting process for special requirements

Compared to dry cut-off grinding, the wet cut-off process guarantees particularly gentle workpiece treatment for polished surfaces. By rinsing the workpieces with coolant and extinguishing the sparks, the hot grinding particles are directly cooled and removed from the surface. This prevents caking, welding or sintering of the resulting spark particles with the ground or polished surface.

Your benefit:

Shortest cycle times due to NC-controlled cuts

Flexible configuration with manual or automatic infeed

Good accessibility for maintenance and cleaning activities

Low maintenance spindle due to lifetime lubrication

Durable inclined board machine stands in heavy welded design for optimum chip and coolant removal

Sealed drive compartment i.e. the drive motor and control components are not located in the wet work area

Your contact person

Rafael Dineiger

Sales Manager International

| Tel.: | +49 7309 875 - 17 |

| Mail: | rdineiger@reichmann.com |