laterally adjustable work table with integrated parking brake

exact cut: line laser projects cut line onto the workpiece

flexible processing due to optionally available inclination of the cut-off wheel from +30° to -45

horizontal adjustment of the cutting head via a gear motor, 300 mm forward/backward each for adaptation to the workpiece

clamping table rotatable by 180°

soundproof cabin with connection for exhaust system

laterally adjustable work table with integrated parking brake

exact cut: line laser projects cut line onto the workpiece

flexible processing due to optionally available inclination of the cut-off wheel from +30° to -45

horizontal adjustment of the cutting head via a gear motor, 300 mm forward/backward each for adaptation to the workpiece

clamping table rotatable by 180°

soundproof cabin with connection for exhaust system

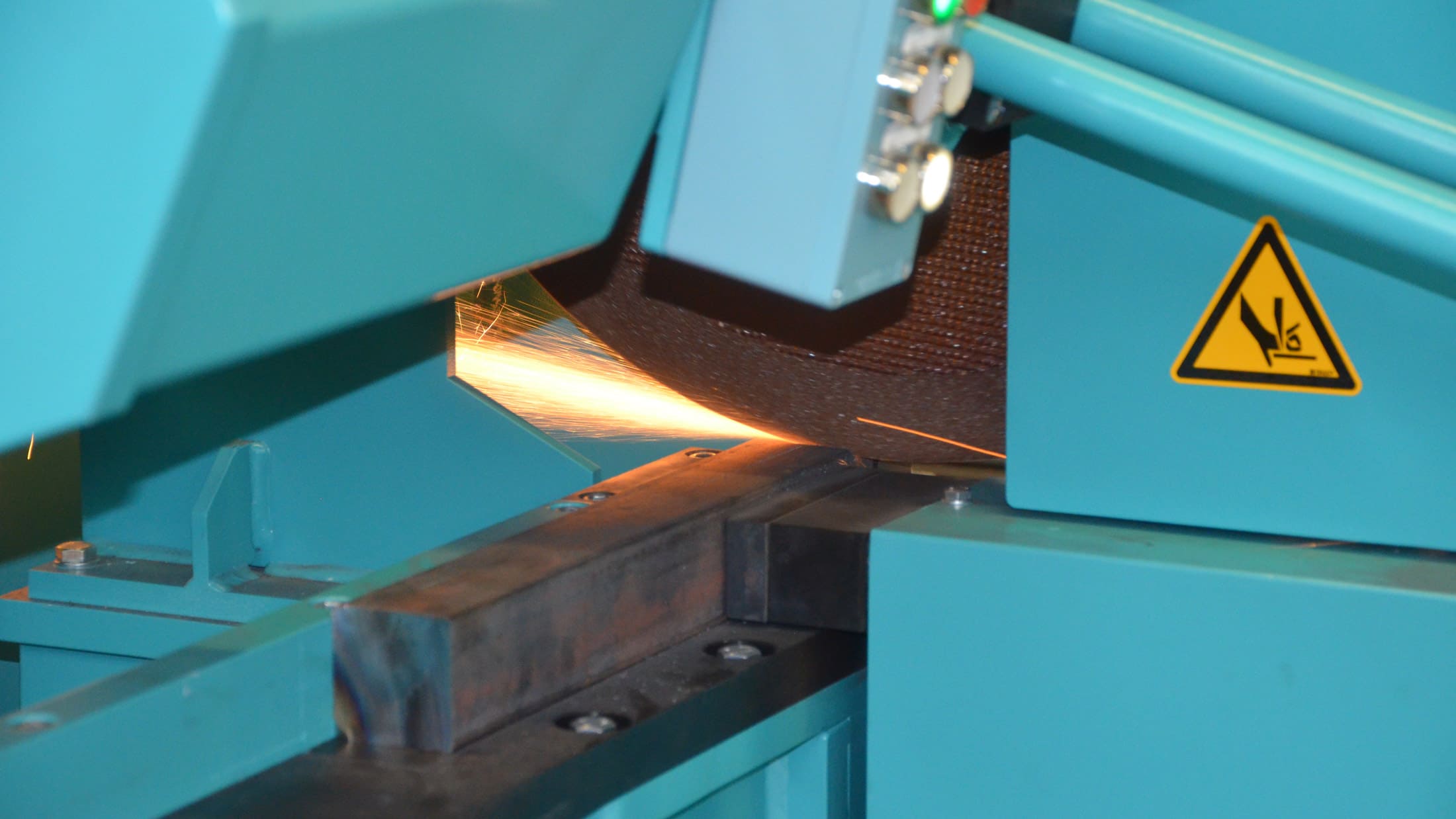

The stationary pendulum cutting-off machines with laterally movable work table are used for cutting off sprues and risers on castings, for cutting up cast bunches, for crushing recirculating material and similar applications that frequently occur in foundries.

The workpieces to be separated are clamped on the work table with suitable clamping devices. For loading and unloading the workpieces, the table (with integrated roller carriage) is moved to the side by means of a handwheel. A pneumatic brake holds the table securely in the set position. By releasing the brake, the cutting position can be approached easily and quickly. All pendulum cut-off machines can be equipped with both straight and cranked cut-off wheels. For an even more universal use, an inclined position of the cutting head +30/-45° with lifting gear and remote control is available as an option.

Your benefits:

Robust machine design for foundry environment

The spindle bearings and the belt drive are maintenance-free, thus reducing operating costs

Low-vibration handles for user-friendly operation

Quick and easy positioning of the workpieces due to the laterally movable work table

exact cut: display of the cutting line before cutting by a line laser

Central control element enables easy operation

TECHNICAL DATA

| TYPE | RATING KW | CUTTING SPEED | CUTTING DISC DIAMETER |

| PTS 500/ST | 22 | 80 m/s | 500 mm |

| PTS 600/ST | 45 | 80 m/s | 600 mm |

Your contact person

Rafael Dineiger

Sales Manager International

| Tel.: | +49 7309 875 - 17 |

| Mail: | rdineiger@reichmann.com |