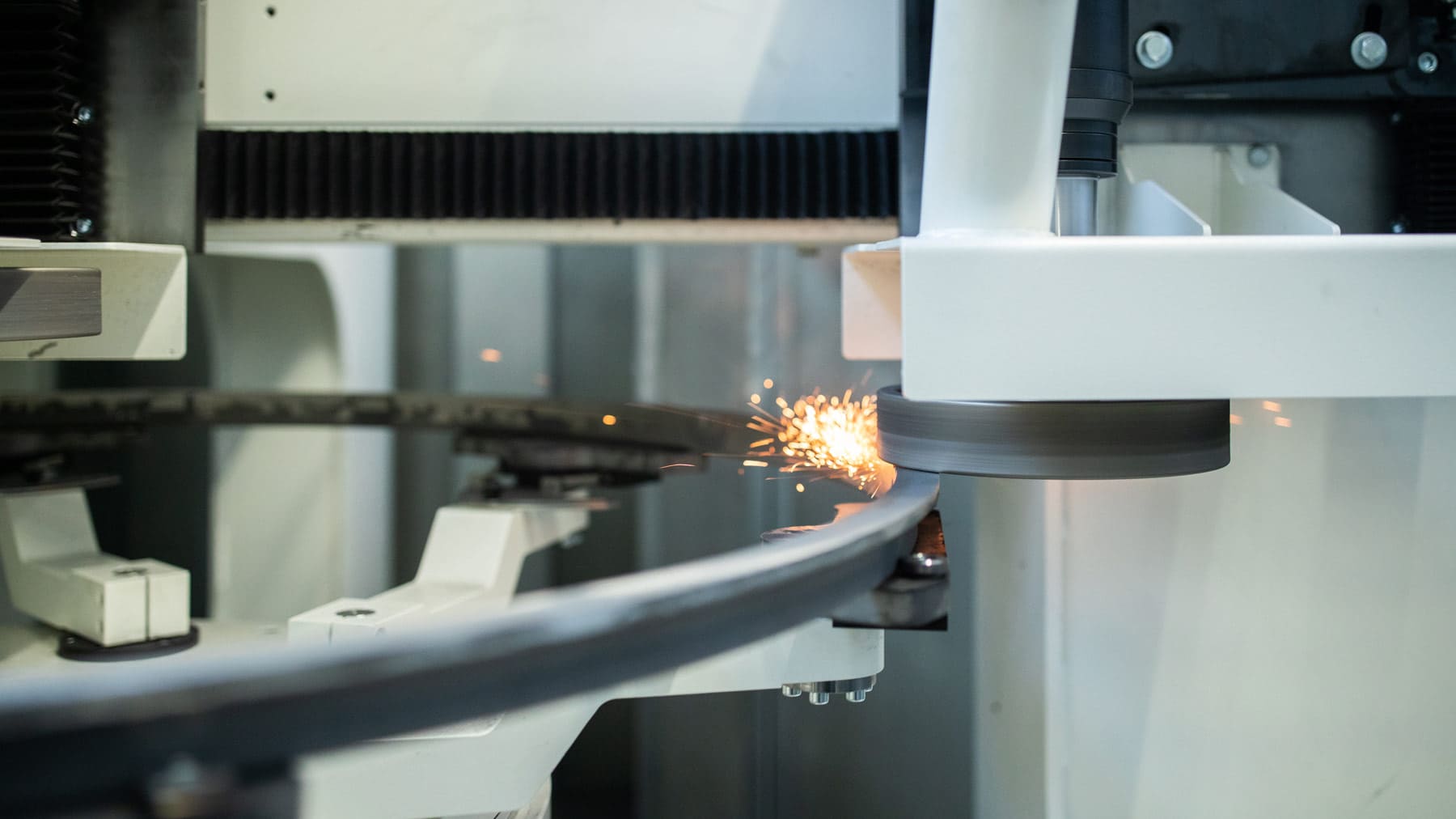

Cutting and grinding machines for superalloys and wear castings

Superalloys are complex compositions based on nickel, cobalt or iron and are used for high-temperature applications or where there are high mechanical stresses. Typical components such as seals or engine parts are found in the energy sector or in the aerospace industry.

Wear cast iron or white cast iron is characterized by its particular hardness and is therefore also suitable for very high stresses. The high wear resistance of these castings is in great demand in high-end mechanical engineering.

Discover our solutions for cutting and fettling superalloys and wear castings.

Cut-off machines TS

Specific cut-off machine for single loading or with loading and unloading table. Different designs from the manual to the fully automatic cut-off system allow an optimal adaptation to your requirements and your workpiece. Due to the high cutting performance of the Reichmann systems, risers and sprue residues are precisely cut off without blue grinding.

Round part grinding machines RFG

Round part grinding machine for specific round part machining on the outside, inside and on the head surface. The rigid chuck has a large useful range and a centering effect. Thus, the round part is brought into shape during grinding.

Cylindrical grinding machines AS

The automatic grinding machine AS grinds bar material made of chrome-nickel alloys on the outer diameter and on the front surface.

High pressure belt grinding machines HBM

Reichmann uses the high-pressure belt grinding process for the removal of sprue protrusions. High-pressure belt grinding guarantees the highest removal rates and the longest tool life.

Automatic grinding center Maus 900-2200

The Maus casting finishing center is designed for flexible cutting and grinding of castings with up to three tools. The fettling center offers high flexibility for small to medium production numbers and fast teach-in for new castings. Machining takes place efficiently in parallel with loading and unloading.

Robot Center

The Robot Center offers flexible options for robot-based grinding and cutting of castings in small to medium production volumes. Machining takes place efficiently in parallel with loading and unloading.

Surface belt grinding machines BS

The surface belt sanders of the BS series are characterized by a robust design and user-friendly handling. The quick and easy change of the sanding belt allows an economical use in the industry, in the trade and by professional craftsmen.

Rough grinding machines 600 SK

Manual grinding machine for workpiece-guided machining of castings primarily on the outside diameter. The robust standard machine for every foundry.