Every day, more than 650000 brake discs are ground on Reichmann machines worldwide

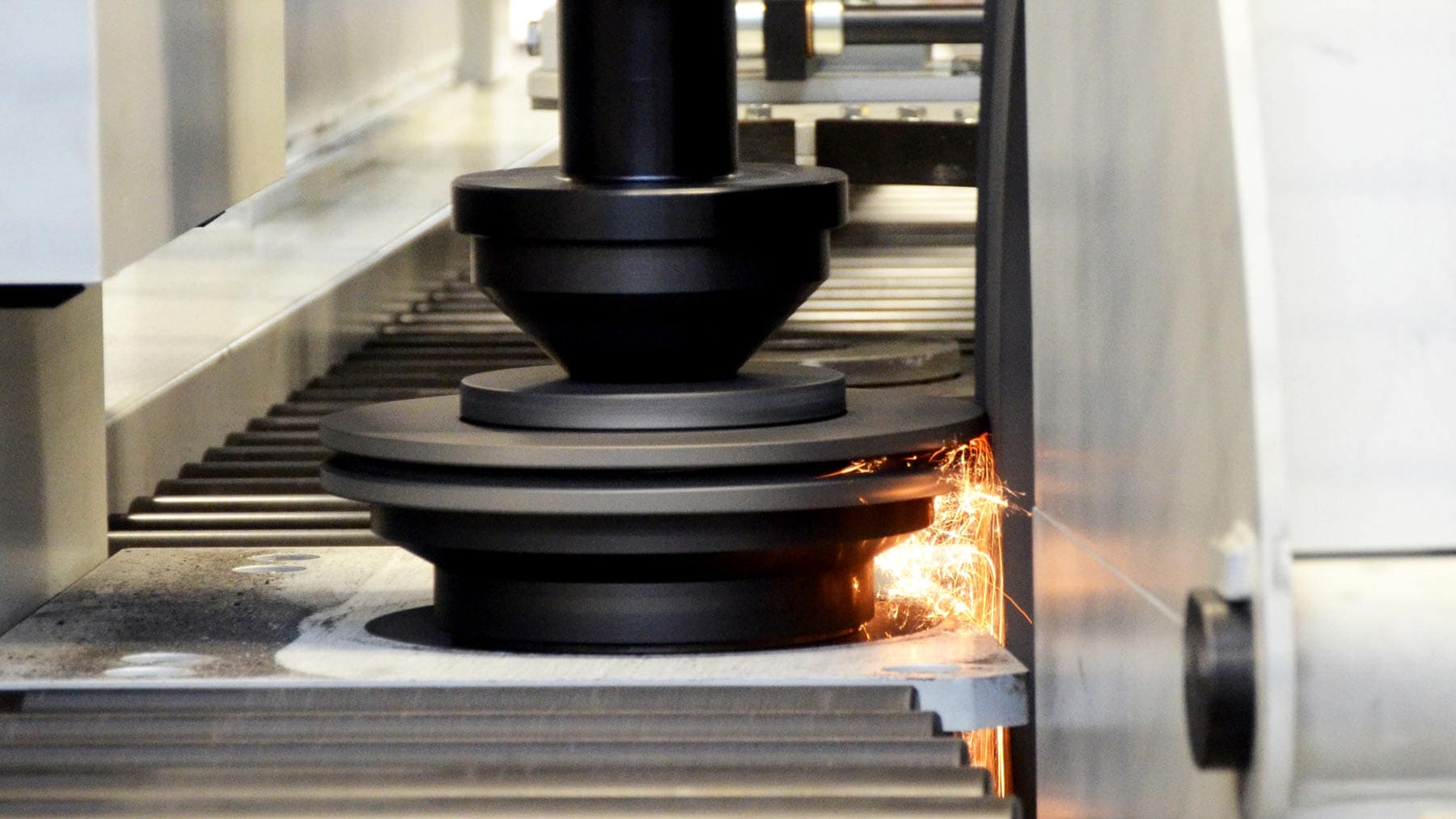

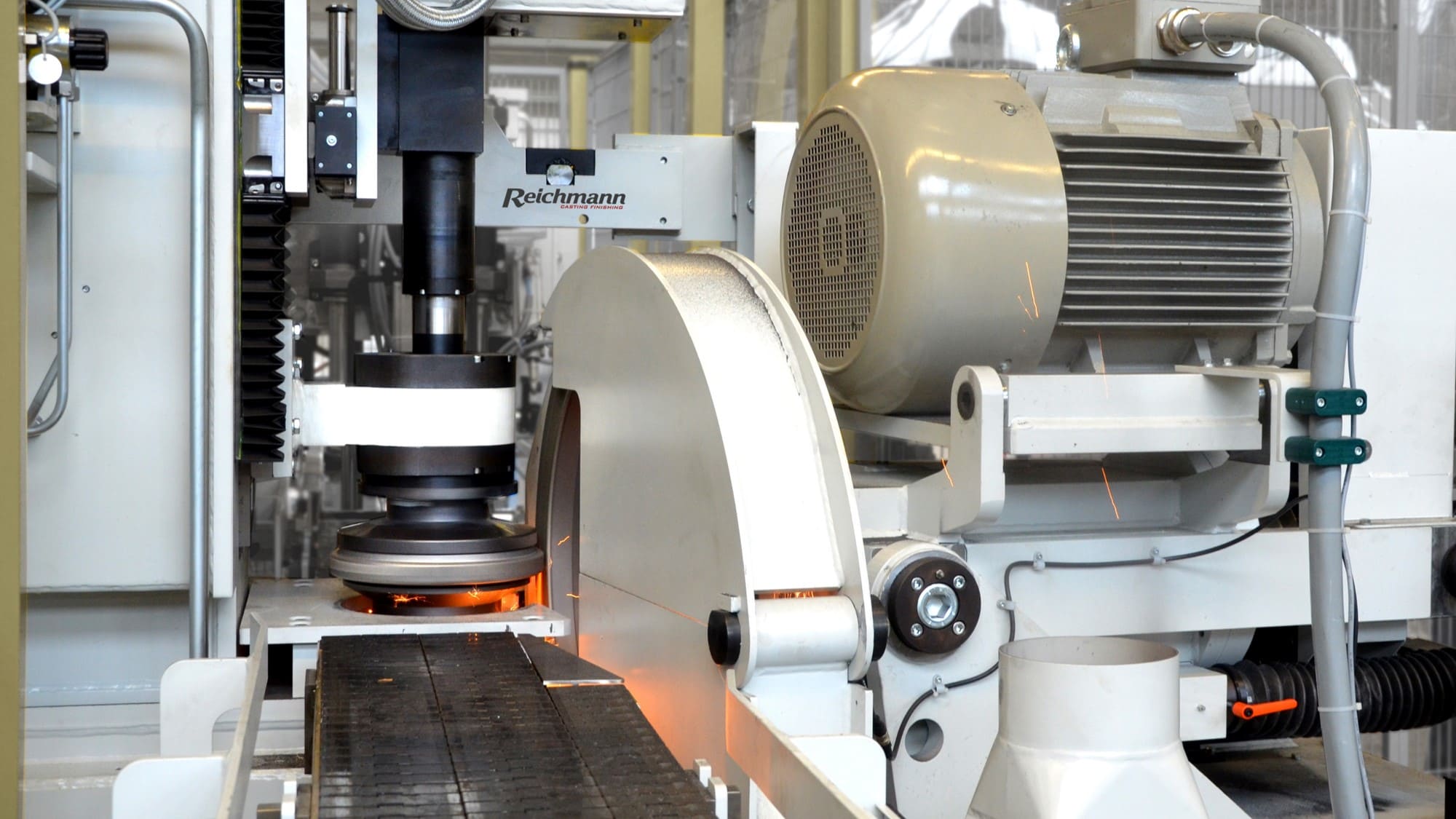

The fully automatic deburring grinding machines of the S1 line effectively remove burrs and sprue residues on round parts of the foundry industry such as brake discs, brake drums, flywheels, hubs or clutch carrier plates. Reichmann S1 systems guarantee highest availability and reliable grinding results in continuous operation at customers worldwide. Currently, most brake discs and brake drums for passenger cars and the commercial vehicle sector worldwide are deburred with Reichmann S1 round part grinding systems in a process-safe manner.

99,4%

availability 24/7

on annual average (2021)

5

seconds minimum

cycle time per casting

220 - 420

mm Diameter

for car round parts

280 - 550

tools or optional

mm Diameter for truck round parts

deburring on the inner and outer diameter possible

option: automatic grinding wheel measurement for grinding wheel wear compensation guarantees long service life

machining of a wide range of different round parts

conveyor system to match the casting (rollers, plates, chains)

deburring on the inner and outer diameter possible

option: automatic grinding wheel measurement for grinding wheel wear compensation guarantees long service life

machining of a wide range of different round parts

conveyor system to match the casting (rollers, plates, chains)

Castings

- Brake discs

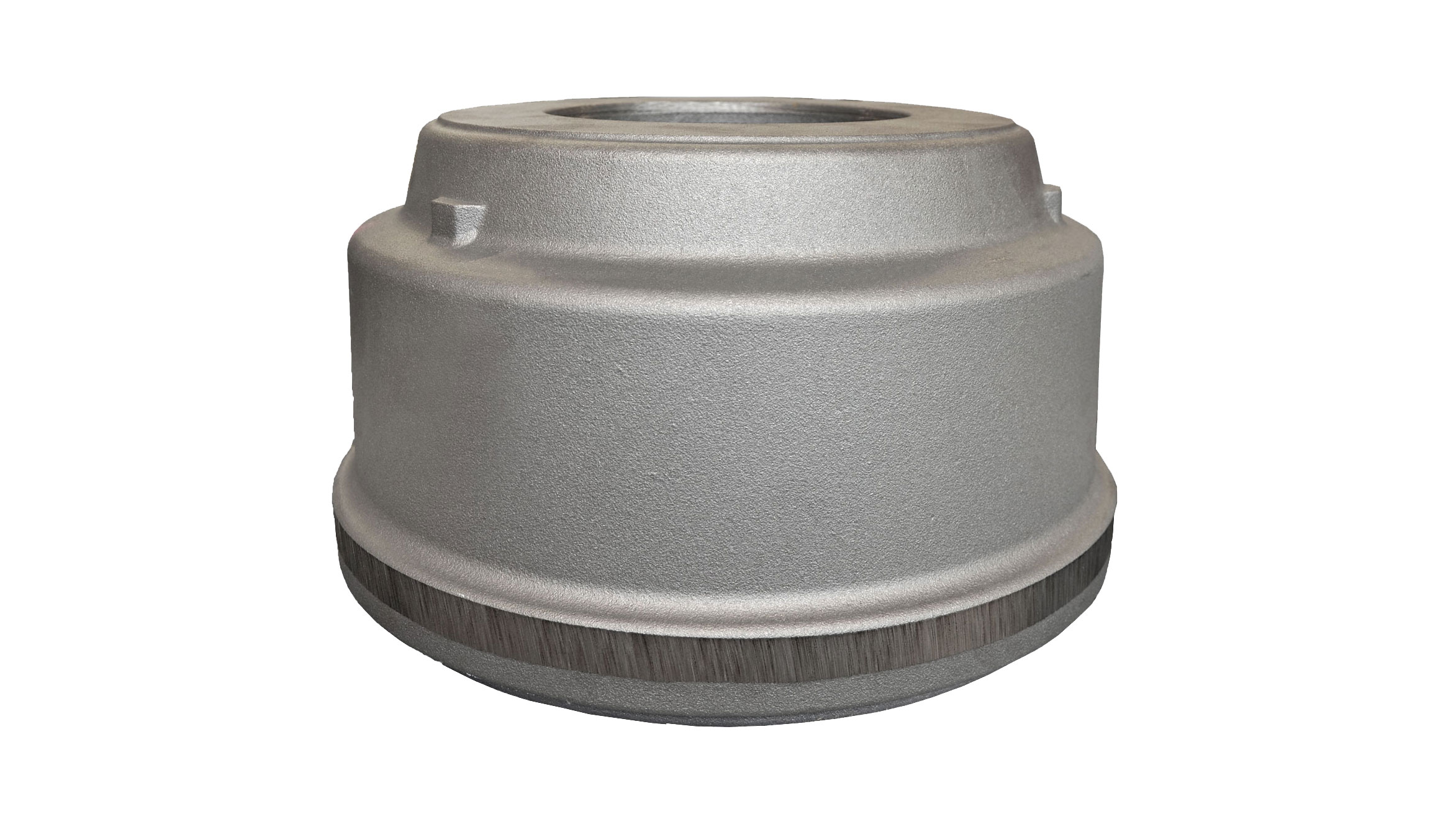

- brake drums

Feeding and discharging the castings

Fully automatic feeding and discharging of castings on hardened steel rollers. Perfect for the environment of a foundry. For castings that cannot be rolled, the Reichmann S1 deburring system can be optionally equipped with a plate or chain conveyor system.

Robot palletizing

The optionally available robotic palletizing system automatically places the brake discs into provided boxes or containers according to predefined stacking patterns. With cycle times of up to 8 seconds for stacking, you accelerate your processes and relieve your personnel.

Your benefits:

extremely short cycle times

fully automatic grinding process with consistent grinding quality

machining on inner and outer diameter possible

long service life thanks to robust design

highest availability in 24 hour continuous operation

quick product change possible

Downloads

Your contact person

Rafael Dineiger

Sales Manager International

| Tel.: | +49 7309 875 - 17 |

| Mail: | rdineiger@reichmann.com |

The Reichmann S1 system has been used reliably in 24-hour continuous operation for many years. The round part grinding system is coupled to the casting cycle and achieves the highest availability of over 98% according to VDI 3423. With the very short cycle times of only 5-7 seconds per casting, we have significantly increased our throughput and save time and costs. Thanks to the robust mechanical engineering, we can carry out any necessary maintenance work in-house in an uncomplicated and plannable manner.

Eurac Hradec s.r.o

Czech Republic